Head of the Department

Programme Offered

B.Tech Chemical Engineering

Intake - 30

About the Department

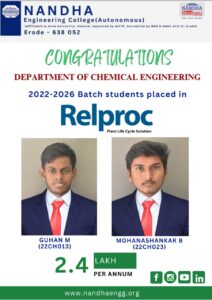

The Department of Chemical Engineering at Nandha Engineering College was established in 2017, with a vision of academic excellence and a commitment to contributing to societal and industrial needs through research. Our goal is to provide students with a balance of intellectual and practical experiences that enable them to serve various societal needs, particularly in rural communities. We have vibrant students and young and dynamic faculty whose expertise spans a wide range of disciplines within the Chemical Science and Engineering stream. Our department fosters a healthy work culture that aims to equip students to become successful employees or entrepreneurs in their chosen fields.

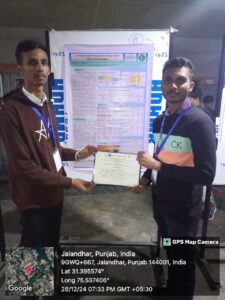

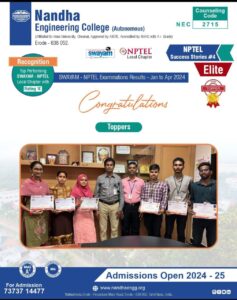

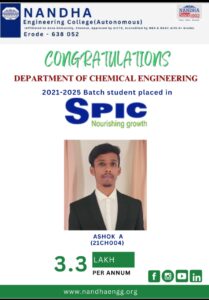

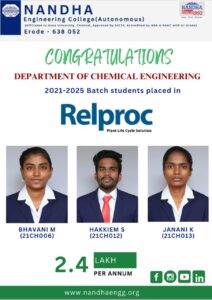

Our students have actively participated in seminars, national and international conferences, and have won numerous Best Paper/Poster awards. Similarly, there has been a dramatic increase in industrial collaboration and consultancy, research projects, research publications, and faculty awards. Additionally, our alumni hold leadership positions across various fields. We firmly believe in our ability to succeed and nurture an attitude of self-reliance, confidence, commitment, and responsibility to the motherland that we serve.

VISION

To produce globally competent engineers in chemical engineering and allied disciplines to meet the growing needs of the society.

MISSION

Department of Chemical Engineering is committed

- To develop skilled and employable graduates to meet the challenges in emerging fields of Engineering and Technology.

- To prepare the students for prosperous career in Engineering and Entrepreneurship by inculcating the leadership qualities with professional and ethical responsibilities for the benefit of the society.

- To provide learner centric environment by imparting quality education to cater the needs of the society.

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

The graduates of Chemical Engineering will be

PEO 1: Core Competency: A successful professional with core competency and inter-disciplinary skills to satisfy the Industrial needs.

PEO 2: Research, Innovation and Entrepreneurship: Capable of identifying technological requirements for the society and providing innovative ideas for real time problems.

PEO 3: Ethics, Human values and Life-long learning: Able to demonstrate ethical practices and managerial skills through continuous learning.

PO 1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals and an engineering specialization to the solution of complex engineering problems.

PO 2: Problem analysis: Identify, formulate, review research literature and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences and engineering sciences.

PO 3: Design / development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety and the cultural, societal and environmental considerations.

PO 4: Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data and synthesis of the information to provide valid conclusions.

PO 5: Modern tool usage: Create, select and apply appropriate techniques, resources and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations.

PO 6: The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO 7: Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts and demonstrate the knowledge and need for the sustainable development.

PO 8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

PO 9: Individual and team work: Function effectively as an individual and as a member or leader in diverse teams and in multidisciplinary settings.

PO 10: Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large such as being able to comprehend and write effective reports and design documentation and make effective presentations and give and receive clear instructions.

PO 11: Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, manage projects and in multidisciplinary environments.

PO 12: Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

The students of Chemical Engineering will be able to

PSO 1: Identify, formulate and analyze the problems of chemical engineering systems and product development.

PSO 2: Implement appropriate engineering tools for modeling, simulation, analysis and optimization of chemical processes.

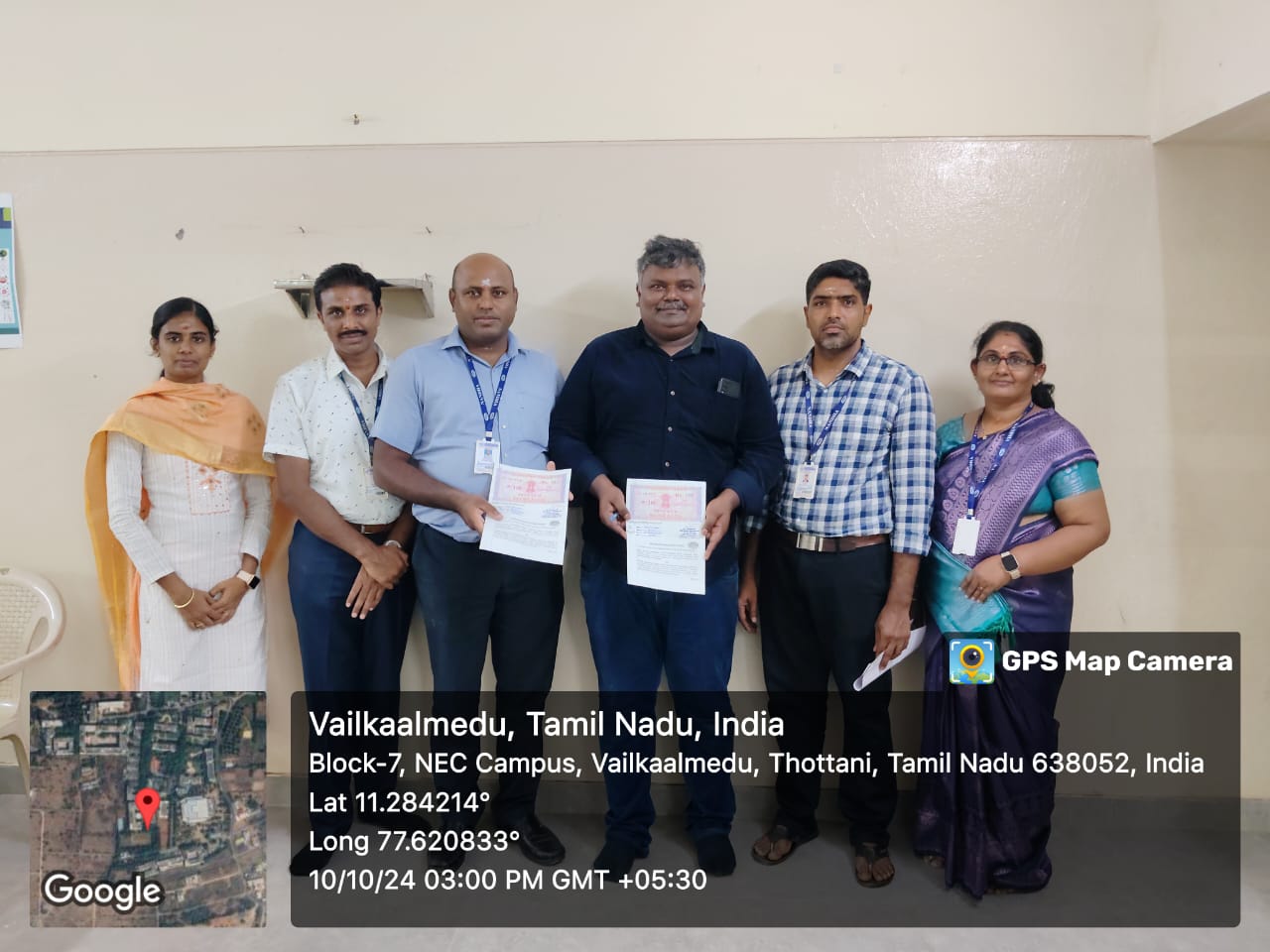

MEMORANDUM OF UNDERSTANDING (MOU)

| S. No | Name of the Company | Date of MoU Signed |

| 1 | Europrogetti India Pvt. Ltd | 15.03.2025 |

| 2 | Petrosky Institute of Plant Engineering | 07.11.2024 |

| 3 | Green Process Technology | 10.10.2024 |

| 4 | Shakthi Knitting Mills – Perundurai | 01.11.2021 |

| 5 | Common Effluent Treatment Plant (CETP) – Perundurai | 01.11.2021 |

| 6 | SIM Infosystems Private Ltd., Chennai-600 041 | 01.11.2021 |

| 7 | Fermion Energy & Engineering Solutions Pvt. Ltd., Coimbatore-641042 | 01.11.2021 |

| 8 | Prime Industries (Waste tyre pyrolysis Unit), SIPCOT, Perundurai-638052 | 01.11.2021 |

Supporting Staff Members

Ms.Meenakshi P

Ms.Kalaivani G

Mr.Suvendiran R

Mr.Sathishkumar C

Department Laboratory

FLUID MECHANICS LABORATORY

Fluid Mechanics laboratory involves in to examine the properties of fluids and to conduct experiments involving both incompressible and compressible flow.

The facilities available in this laboratory: venturimeter, orifice meter, notch, flow through straight pipe, flow through concentric pipes, flow through Spiral and helical coil, packed bed, fluidized bed, centrifugal pump, reciprocating pump.

CHEMICAL ANALYSIS LABORATORY

Instruments and facilities available in this laboratory nurture the students with a practical

knowledge of Inorganic, Organic, Physical Chemistry, and petroleum products testing. This laboratory is intended to facilitate research for students and scholars in tackling crucial topics related to environmental sustainability. This laboratory helps the students in designing and implementing environmentally friendly chemical processes, as well as instils the use of green technologies to promote the development of sustainable systems.

The facilities available in this laboratory: Cleveland Open Cup Apparatus, Pensky Martens Closed Cup Apparatus, Cloud and Pour Point Apparatus, Saybolt Viscometer, Redwood Viscometer, Digital Rotational Viscometer, Kinematic Viscometer, ABBE Refractometer, Kjeldahl Apparatus, Orsat Apparatus, Bomb Calorimeter, Flame photometer, COD Apparatus, Melting/ Boiling Point Apparatus, Aniline Point Apparatus, Conductivity meter, Nephelometer, Polarimeter, UV- Vis Spectrophotometer, Hot Air Oven, Muffle Furnace,

HEAT TRANSFER LABORATORY:

Heat Transfer Laboratory involves in estimate individual and overall heat transfer coefficient through experiments and to study about the radiation heat transfer and calculate Stefan-Boltzmann constant also to know the performance of heat exchangers and evaporators

The facilities available in this laboratory: Shell and Tube heat exchanger, double pipe heat exchanger, evaporator, horizontal and vertical condenser, jacketed vessel, extended surface and Packed Column.

MECHANICAL OPERATIONS LABORATORY

Mechanical Operations Laboratory involves handling and processing of particulate solids which form the major components of production processes in Chemical industries and deals the insight knowledge on different types of mechanical operations like solid- solid separation and solid – fluid separations.

The facilities available in this laboratory: Jaw crusher, crushing rolls, ball mill, plate and frame filter press, vacuum leaf filter, vacuum rotary drum filter, batch sedimentation test, cyclone separator, froth flotation and air permeability apparatus.

CHEMICAL REACTION ENGINEERING LABORATORY

Chemical Reaction Engineering Laboratory aims in to determine the rate constant of batch reactor for reversible and irreversible reactions and understand the behaviour of PFR and MFR for the saponification reaction also to determine the performance of combined reactors.

The facilities available in this laboratory: Batch Reactor, Combined Reactors (PFR Followed by MFR & MFR Followed by PFR), Semi Batch Reactor, Mixed Flow Reactor, Plug Flow Reactor, Solid – Liquid Non Catalytic Reactor and Adiabatic Reactor.

MASS TRANSFER LABORATORY

Mass Transfer Laboratory involves to develop sound practical knowledge on different types of mass transfer equipments and to understand the basic principle in the mass transfer like distillation, extraction/leaching and drying operations. This experimental study equips the students with the necessary input for the design/operation of complex equipments involved in the process industries.

The facilities available in this laboratory: Diffusivity, Wetted wall column, distillation setup, steam distillation apparatus set up, Co-current /Counter – current Leaching studies, liquid-liquid extraction studies in Rotating Disc Contactor, Surface Evaporation, Batch Adsorption study and Vacuum Dryer.

PROCESS CONTROL LABORATORY

Process Control Laboratory involves in to the get knowledge about the principles of controllers and to determine the time constant for first order and second order system also to analysis the performance behaviour of P, PI, PD, PID & ON-OFF controller also to learn the transient response of chemical system and controller.

The facilities available in this laboratory: ON-OFF control, control valve characteristics, Non-interacting and Interacting system, Pressure control trainer, Temperature control trainer, Cascade Control trainer, Flow control trainer, Level control trainer.

PROCESS MODELING AND SIMULATION LABORATORY and PROCESS COMPUTATION LABORATORY

This laboratory aims to explore knowledge in simulating equipments used in process industries to perform the mathematical calculations using software and to learn the basic chemical calculations using spreadsheet and to develop a process flow and process Instrumentation diagrams using software.