About the Department

DEPARTMENT OF MECHANICAL ENGINEERING

The Department of Mechanical Engineering was established in the year 2005. At present, the department offers Graduate Programme – B.E., in Mechanical Engineering, Post Graduate Programme – M.E, in Engineering Design and Doctorate Programme – Ph.D., in Mechanical Engineering. The department has been accredited by National Board of Accreditation (NBA) in the year 2013. It is reputed for producing Engineers as Professionals, Researchers and Entrepreneurs. Many of its alumni play key roles in Industries and Institutions in India as well as abroad. The department is proud to be collaborated with well-known Industries and Institutions in the emerging fields of Mechanical Engineering.

With a right combination of theory, practical, projects (hands-on) and industrial training in the areas such as Design, Thermal, Manufacturing and Energy Engineering, this programme has well placed itself as a well-known preference for the students.

VISION

To be recognised as a centre of excellence in the field of Mechanical Engineering and to produce competent engineers with multi-disciplinary exposure to meet the changing needs of society.

MISSION

- To enrich technical knowledge and skills by imparting quality education with ethics and social responsibility.

- To empower students in the thrust areas of Mechanical, Allied Engineering, and Entrepreneurship in the continually changing global market.

- To provide a conducive learning environment for continual improvement to cater to the needs of society.

PROGRAMME EDUCATIONAL OBJECTIVES (PEOs)

The graduates of Mechanical Engineering will be

PEO 1: Core Competency: A successful professional with core competency and inter-disciplinary skills to satisfy industrial needs.

PEO 2: Research, Innovation and Entrepreneurship: Capable of identifying technological requirements for society and providing innovative solutions to real-time problems.

PEO 3: Ethics, Human values and Life-long learning: Able to apply professional and ethical practices in their career through continuous learning.

PROGRAM OUTCOMES (POs)

PO 1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to solve complex engineering problems.

PO 2: Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems, reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

PO 3: Design / development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for public health, safety, and cultural, societal, and environmental considerations.

PO 4: Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of information to provide valid conclusions.

PO 5: Modern tool usage: Create, select and apply appropriate techniques, resources, and modern engineering and IT tools to complex engineering activities with an understanding of the limitations.

PO 6: The engineer and society: Apply reasoning informed by contextual knowledge to assess societal, health, safety, legal, and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

PO 7: Environment and sustainability: Understand the impact of professional engineering solutions in societal and environmental contexts and demonstrate the knowledge and need for sustainable development.

PO 8: Ethics: Apply ethical principles and commit to professional ethics, responsibilities, and norms of the engineering practice.

PO 9: Individual and team work: Function effectively as an individual and as a member or leader in diverse teams and multidisciplinary settings.

PO 10: Communication: Communicate effectively on complex engineering activities with the engineering community and society at large, including the ability to comprehend and write effective reports, design documentation, make presentations, and give and receive clear instructions.

PO 11: Project management and finance: Demonstrate knowledge and understanding of engineering and management principles and apply these to one’s own work, as a member and leader in a team, manage projects, and in multidisciplinary environments.

PO 12: Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and lifelong learning in the broadest context of technological change.

PROGRAM SPECIFIC OUTCOMES (PSOs)

PSO 1: Identify, formulate, and analyze the problems of Mechanical, Allied Engineering systems and product development.

PSO 2: Apply appropriate computer-aided engineering tools for modeling, simulation, analysis, and manufacturing techniques to solve engineering problems.

PROGRAMMES OFFERED

B.E. – MECHANICAL ENGINEERING

Duration:

- 4 years (Regular) / 3 Years (Lateral Entry)

No. of Semesters:

- 8 (Regular) / 6 (Lateral Entry)

No. of Seats:

- Total – 60

Eligibility:

- As per the Anna University and AICTE Norms.

Scope for Higher Studies after Bachelor Degree:

- M.E. / M.Tech. / M.B.A.

M.E. – ENGINEERING DESIGN

Duration:

- 2 years (Full Time)

No. of Semesters:

- 4 (Full Time)

No. of Seats:

- Total – 6

Eligibility:

- As per the Anna University and AICTE Norms.

Scope for Higher Studies after Master Degree:

- Ph.D. (Full Time/Part Time)

Eligibility:

- As per the Anna University and AICTE Norms.

SYLLABUS

R22 – Mechanical Engineering Curriculum & Syllabus – 2024 batch onwards

R22 BE – Mechanical Engineering curriculum & Syllabus (2022 – 2026, 2023 – 2027 batches)

R17 BE – Mechanical Engineering

R17 BE – Mechanical Engineering (Open Electives)

R15 BE – Mechanical Engineering

MECH-FACULTY DETAILS

LIST OF FACULTY MEMBERS

ACADEMIC YEAR 2024 – 2025

| S.No. | Staff Name | Designation | Qualification |

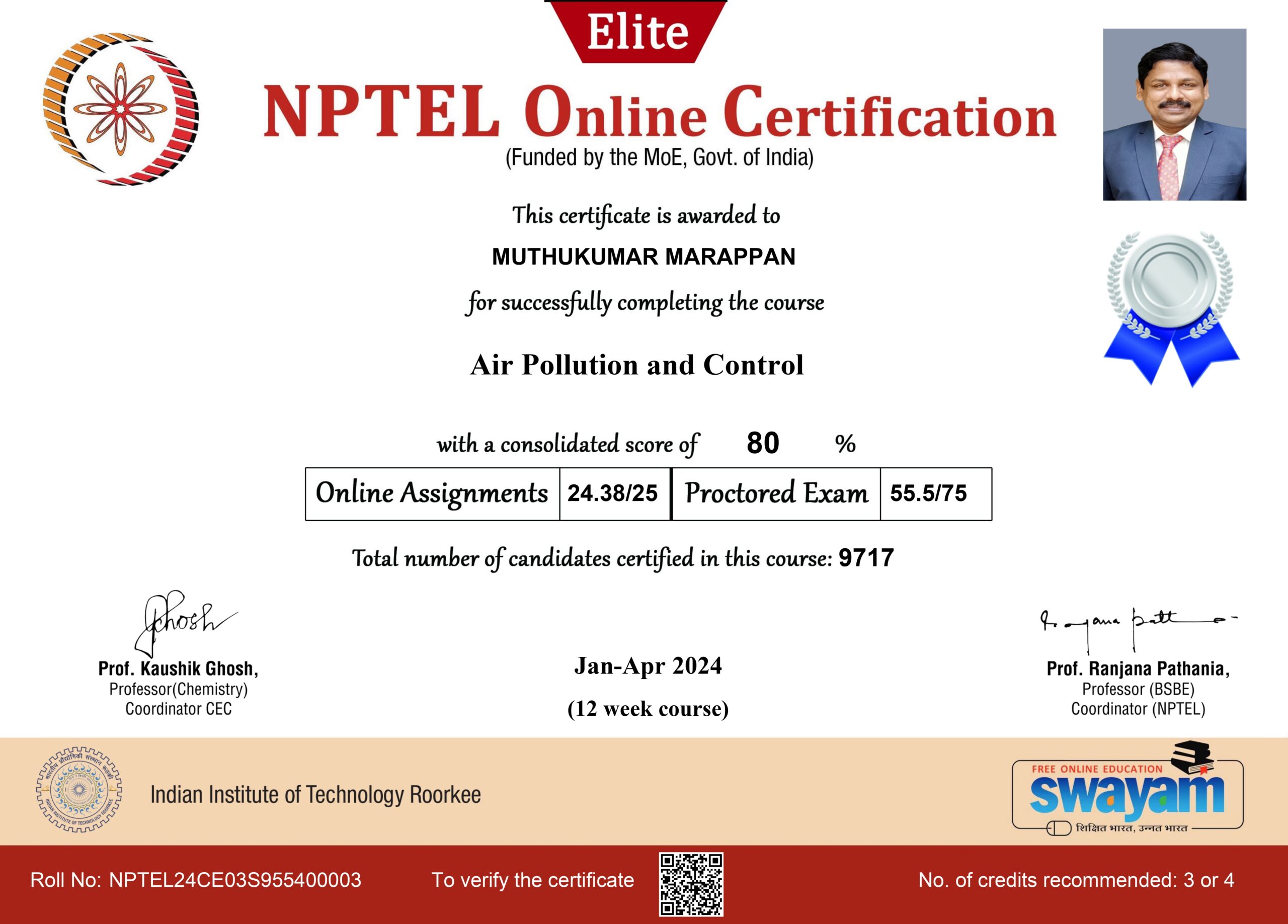

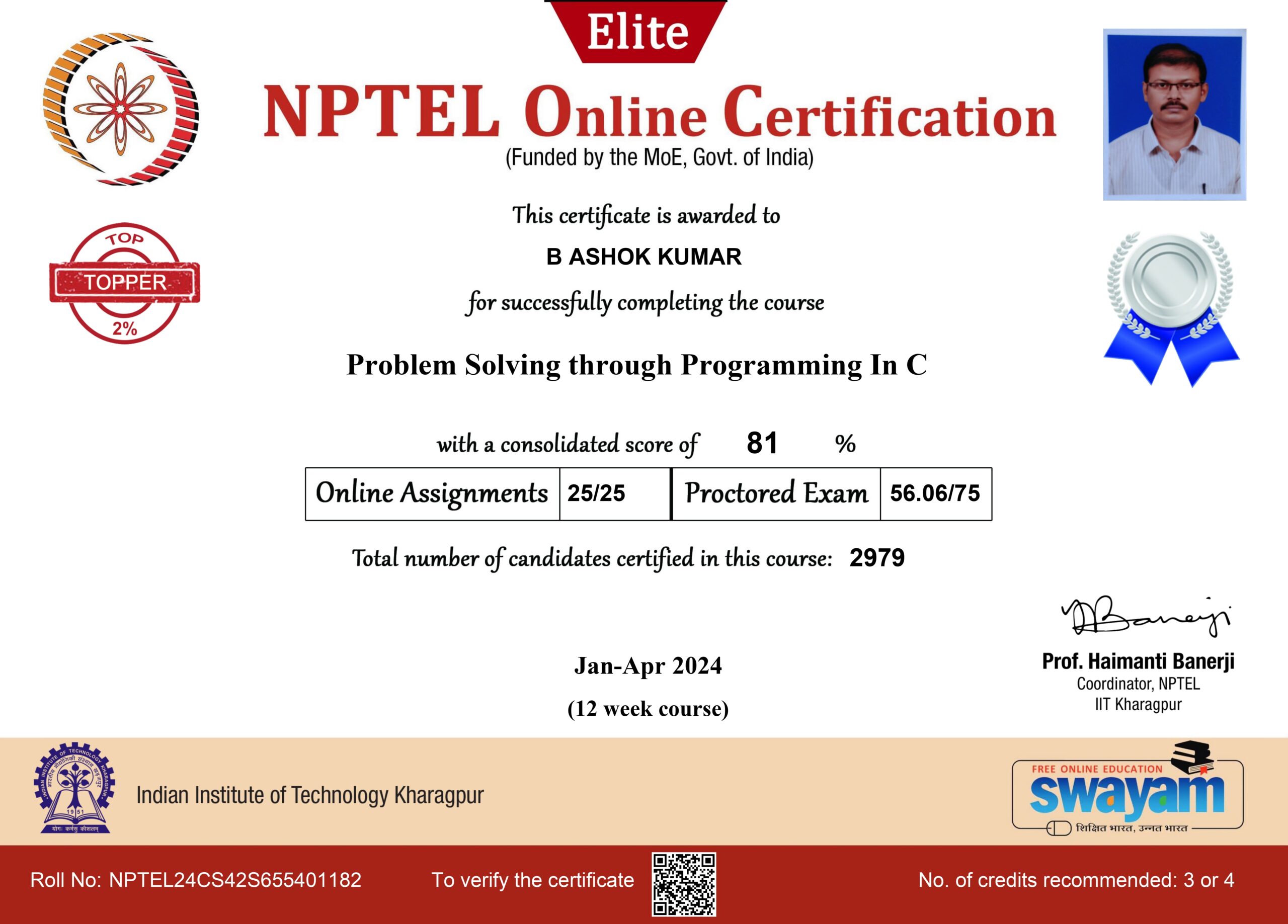

| 1 | Dr.Muthukumar M | Prof & HOD | M.E., PhD. |

| 2 | Dr.Easwaramoorthi M | Prof | M.E., PhD. |

| 3 | Dr.Ashok Kumar B | Prof | M.E., PhD. |

| 4 | Dr.Magibalan S | ASP | M.E., PhD. |

| 5 | Dr.Senniangiri N | ASP | M.E., PhD. |

| 6 | Dr.Manikandan M | ASP | M.E., PhD. |

| 7 | Mr.Loganathan V N | AP | M.E. |

| 8 | Mr.Shanmugam M | AP | M.E., (PhD.) |

| 9 | Mr.Sengottaiyan M | AP | M.E. |

| 10 | Mr.Eswaran S | AP | M.E. |

| 11 | Mr.Muruganantham S | AP | M.E. |

| 12 | Mr.Mohamed Ajmal Mahasin M | AP | M.E |

| 13 | Mr.Ravichandran D | AP | M.E. |

| 14 | Mr.Velliyangiri B | AP | M.E.,(PhD.) |

| 15 | Mr.Arjun Raj R | AP | M.E. |

| 16 | Mr.Balakrishnan S | AP | M.E.,(PhD.) |

| 17 | Mr.Venkateshan T | AP | M.E. |

| 18 | Mr.Rajkumar R | AP | M.E |

Board of Studies

CORE STRENGTH

The department of Mechanical Engineering has core strength in the following thrust areas.

- Lean Manufacturing

- Fuel cells

- Alternative fuels

- Solar thermal systems

- Welding

- Composite Materials

- 3D Printing

- Tribology

It helps the students to do application oriented real time quality projects and research projects.

- The department has industrial experts as Visiting Professors/ Adjunct Faculty to inculcate the skill sets at par with industry standards.

- Strong industry link with industries located in and around D college which is practicing latest Mechanical Engineering tools and technologies. It provides hands-on training opportunity to the students.

- Providing Project Based Learning (PBL) mode of teaching helps the students to acquire hands-on experience.

- Core placement assistance team in the department helps the students to get settled in their career through internships cum placement.

- Linkage with leading universities.

Department Library

A well-equipped library is functioning in the department, in addition to the central library, to meet the needs of students, faculty members, and research scholars. The department library has 805 books in various disciplines of Mechanical Engineering, including Design, Manufacturing, Thermal, Fluid Power, Industrial Engineering, Nano Technology, Mechatronics, and Robotics. Details about the national and international journals and magazines available in the main library are also maintained in the department library. Additionally, around 750 students’ project reports and NPTEL videos are kept in the department library for reference.

Roll of Honours

RANK HOLDERS

| BATCH | STUDENT NAME | PERCENTAGE / CGPA |

| 2005-2009 | SAKTHIVEL.S | 81% |

| 2006-2010 | YUVARAJ.G | 78% |

| 2007-2011 | THIYAGARAJAN.A | 9.30 CGPA |

| 2008-2012 | SARAVANAKUMAR.T.P | 9.08 CGPA |

| 2009-2013 | RAJALINGAM.S | 8.91 CGPA |

| 2010-2014 | LOKESHKUMAR.R | 8.86 CGPA |

| 2011-2015 | BOOPATHI.R | 8.37 CGPA |

| 2012-2016 | ARIHARASUDHAN.M | 8.74 CGPA |

| 2013-2017 | JAGATHESWARAN.S | 9.18 CGPA |

| 2014-2018 | VENKATESH.K | 9.31 CGPA |

| 2015-2019 | KESAVAMOORTHY.R | 9.16 CGPA |

| 2016-2020 | KAVIN.G | 9.30 CGPA |

| 2017-2021 | SURENDAR.M | 9.68 CGPA |

| 2018-2022 | MONISHA.K | 9.81 CGPA |

| 2019-2023 | PAVITHRAN.S | 9.52 CGPA |

| 2020-2024 | MERLIN ABINAYA.D.V | 9.83 CGPA |

Placement Details

| Academic Year | Number of Students Placed | View Details |

| 2023-2024 | 88 | Click Here |

| 2022-2023 | 103 | Click Here |

| 2021-2022 | 98 | Click Here |

Renewable Energy Laboratory Sponsored by Saran Solar Solutions

Students Activities

Professional Bodies

Newsletter 2021-2022

Newsletter 2020-2021

Newsletter 2019-2020

Newsletter 2018-2019

Newsletter 2017-2018

Magazine

2024-2025

Odd Semester

2023-2024

Odd Semester

Even Semester

2022-2023

Odd Semester

Even Semester

2021-2022

Odd Semester

Even Semester

CAREER TRENDS

Mechanical Engineers are getting more jobs which are in manufacturing machinery, transportation equipment, computer and electronic products, and fabricated metal products manufacturing industries. Practically every company that designs and produces a product employs a mechanical engineer. Mechanical Engineers can also be found in research labs, the military, government, and in other professions such as medicine, law or teaching.

Most mechanical engineering jobs require design experience. When a need comes for a new or improved product, companies call upon mechanical engineers to do the job. Engineers have to push beyond the limits of their previous work and use innovative technology to meet project requirements successfully.

A second major area of employment for mechanical engineers is manufacturing. Manufacturing jobs cover nearly everything involved in developing a product, from selecting the appropriate materials to choosing the correct machinery to manufacture the product. Most mechanical engineers in this industry work for equipment manufacturers, aerospace companies, utilities, material processing plants, transportation companies, and petroleum companies. They also work with small firms, consulting practices, universities, and government research labs.

Specific assignments might involve research and development, design of equipment or systems, supervision of production, plant engineering, administration, sales engineering, the testing and evaluation of machines and entire plants. Some mechanical engineering titles and their functions include:

Automotive Engineer: Mechanical engineers design many car parts for the automobile industry. As an automotive engineer, He could solve transportation and safety problems by creating better and more efficient engines or by developing improved safety features

Biomedical Engineer: Mechanical engineers work with a variety of medical professionals to design mobility aids, prosthetics, and artificial organs.

Nuclear Engineer: The design of nuclear power plants requires the services of a mechanical engineer. The engineer must understand the fundamentals of nuclear design; know how to operate the plant efficiently, and evaluate the environmental factors associated with nuclear plants.

Robotics Engineer: A mechanical engineer may design machines that build other machines. For instance, a robotics engineer may be involved with creating the devices that are used in assembling automobiles. Engineers are concerned with the robot’s structure, its joint mechanisms, bearings, and heat transfer characteristics.

Teaching: A desire to help mold the next generation of engineers motivates some mechanical engineers to move into academic careers. Engineers in colleges oversee research activities, manage laboratories, and mentor students. They also write and publish books and technical papers about mechanical engineering.

Mechanical engineers can find employment at virtually any institute where innovation takes place. They commonly work in the government, research, industry, military, teaching, management or consulting sectors.

FIELDS WHERE MECHANICAL STUDENTS FIND OPPORTUNITIES FOR PROFESSIONAL GROWTH:

Research and Development (R&D): Engineers whose role is to do research and then plan for new machines and their constituent parts.

Design: Professionals whose responsibility is to draft technical drawings, manually or with the aid of computers.

Production: Engineers who supervise the manufacturing of mechanical components and machines.

Analysis and testing: Engineers who analyze and test different types of machines and their parts to ensure that they function flawlessly.

Installation: Professionals who install machines and mechanical parts at the client location.

Maintenance: Engineers whose primary role is to ensure that machinery works per specifications.

- Automobile and auto part manufacturers

- Aerospace industry

- Various Government sector undertakings

- Aviation companies

- Steel plants

- Thermal plants and gas turbine manufacturers

- Air conditioning and refrigeration industry

- Shipping industry

- Engineering consultancies

- Armed forces

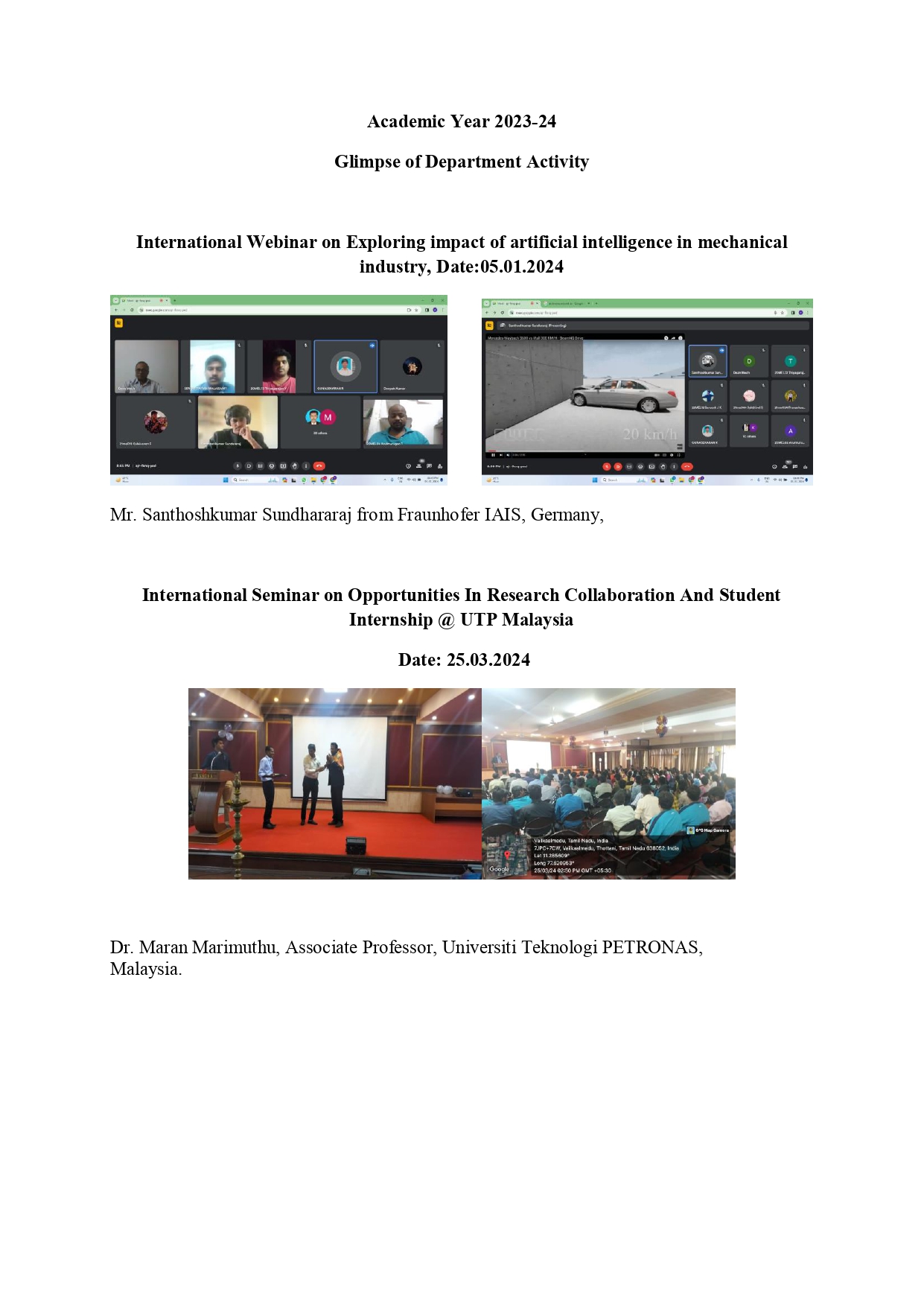

Events

Research Center

Research Approval